Contact No: +91-9561012689

Email Id : info@atechengg.com, operations@atechengg.com

Our Process of Works

MAINTENANCE CONSULTANCY

- Providing Expert Advice on the Planning and Implementation of Maintenance Strategies.

- Our Maintenance Consultancy team provides knowledgeable and seasoned consultants to help plan and implement maintenance management systems.

- We develop efficient, cost-effective maintenance strategies and procedures aimed at minimising downtime.

- Keeping safety, environmental and production impact issues at the forefront of all maintenance activity planning.

We follow a detailed approach in implementation of our work in holistic development of our customers.

IMPLEMENTATION

- Formal assessment of current work procedure & Operation System.

- Understanding the client's current system & Operational practices

- Generating an implementation plan for improvement.

- Field training for operators and Technicians to improve technique.

- Supporting client in setting up key performance indicators.

- Helping clients to improve their system for Growth of Organization.

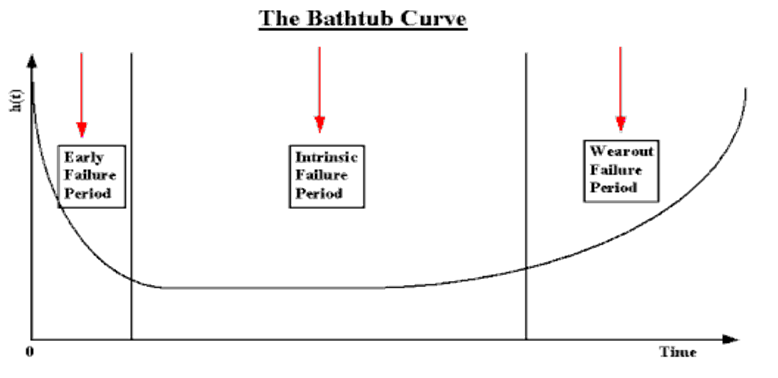

FAILURE ANALYSIS

Our process for problem solving and elimination is known as "Failure Analysis to Eliminate Problems" instead of the commonly used Root Cause Failure Analysis (RCFA).

We believe in Permanent Problem Elimination.

Root Cause Analysis (RCA) indicates analysis of the root cause of a failure. The desired outcome should be to eliminate the problem.

PA/ECCM

Preventive action will directly impact equipment reliability. It all starts with implementing a preventive action program that enables company to identify and minimize equipment/ system failures.

A-TECH’s Preventive Action/Essential Care Condition Monitoring teaches how to set up a cost-effective preventive action in process and provides practical documentation and field execution exercises.